Vacuum Technology for Robotics

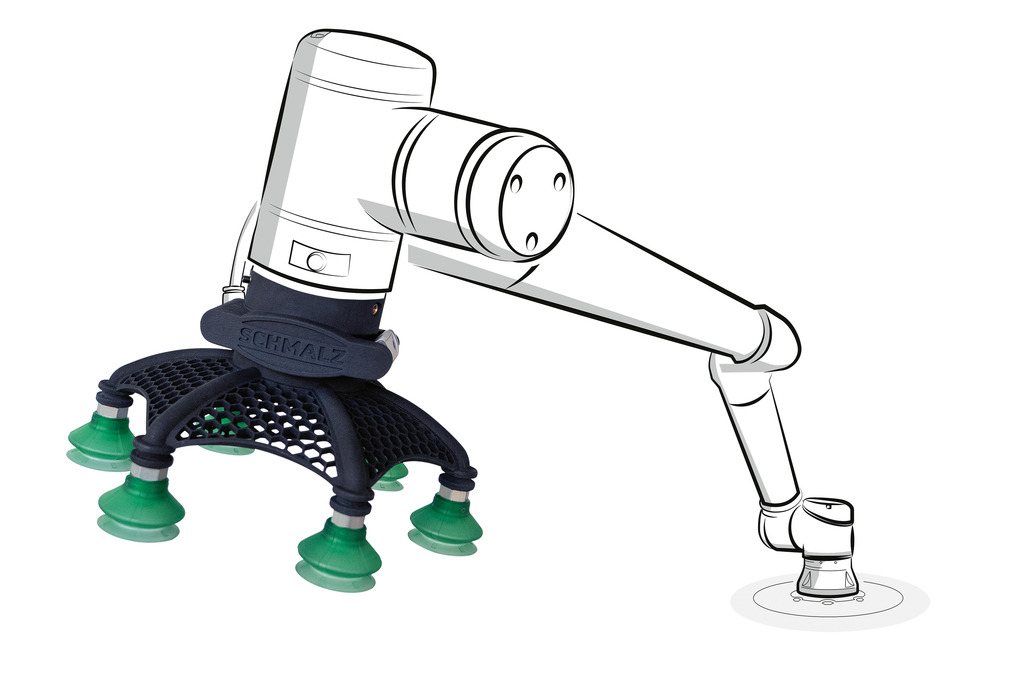

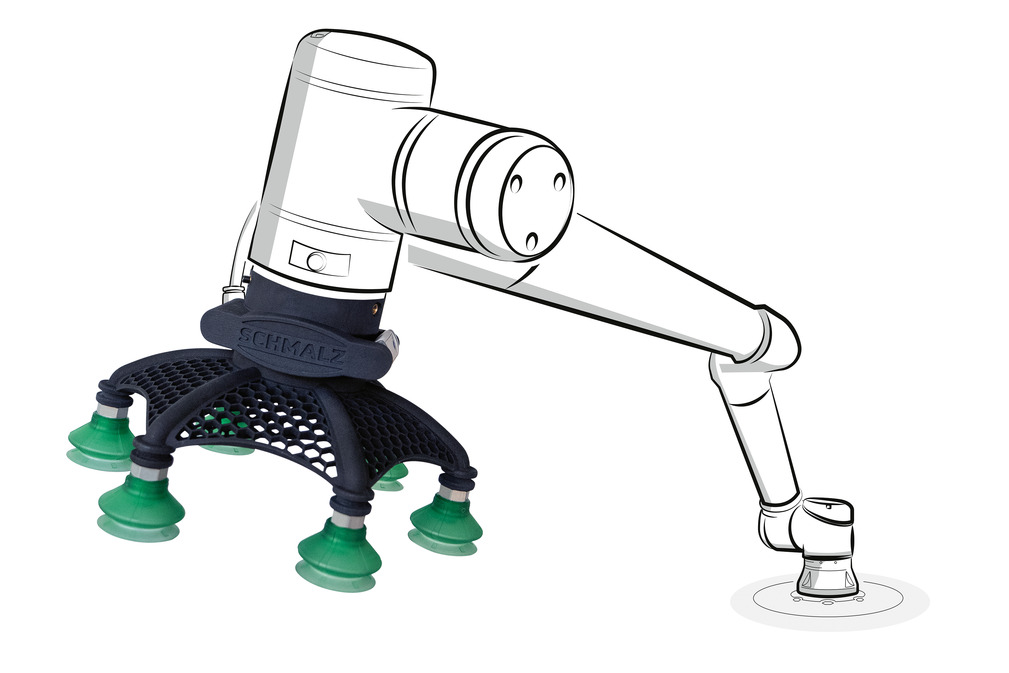

- Individual and flexible vacuum gripping systems for use on lightweight robots and cobots

- Ready-to-connect sets for robot handling and bin picking

Human-robot collaboration (HRC) describes the close cooperation between collaborative robots (cobots) and humans in a shared working environment. This robot technology enables direct interaction between assistant robots and production workers.

The use of industrial robotic systems further advances automation without losing the flexibility and capabilities of humans.

HRC solutions have the potential to revolutionize the industrial world of work and provide humans with targeted support for complex tasks.

HRC systems combine modern robot technology, integrated sensor technology and advanced software to enable safe and precise collaboration between worker and machine. Cobot technologies with sensitive robots detect the proximity of operators and react by adapting their movements, for example by automatically reducing their speed or triggering a holder to avoid potential hazards.

Workpieces or components are handled using specially developed HRC grippers and HRC applicators that are precisely tailored to the respective requirements. In order for these systems to function smoothly, they must first be programmed, set up and installed - a task in which the robot system integrator plays a central role.

The robot system integrator ensures that all components interact optimally and are tailored to the respective use case. The functionality is supplemented by high-precision measuring and gripping technology, which forms the basis for efficient and safe human-robot collaboration.

Human-robot collaboration has found application in many industries, particularly in manufacturing, the automotive industry, medical technology and electronics production. HRC robots are used in areas such as mounting, material handling and loading to automate repetitive and monotonous activities and relieve the worker.

Mobile cobots and stationary cobots play a crucial role, as they are used in both flexible production lines and stationary applications. In certain scenarios, mobile robots can even deliver components autonomously and thus provide efficient support for logistics processes within production.

Depending on the payload, quantities and the specific area of application, the systems can be individually adapted so that they can be seamlessly integrated into existing processes. HRC systems are also suitable for highly sensitive tasks where maximum precision and reliability are required.

Collaborative robots perform repetitive tasks efficiently, increasing productivity and optimizing production lines. In particular, they help to reduce unergonomic work and overhead work, which both promotes employee health and increases efficiency.

Other benefits include noticeable time savings in production and the cost-efficient implementation of the technology. The systems also save space, which allows for optimum use of the available workspace.

The aim is to make production processes more flexible and more economical. The return on investment (ROI) increases due to improved production quality, smooth production processes and the flexible adaptation of the systems to changing requirements. HRC systems also ensure greater setting accuracy and more precise handling, which leads to even better production quality.

Robotics solutions from Schmalz are characterized by maximum precision, safety and process control in the gripping process.

Find answers to questions about automated processes with cobots and vacuum grippers, and how to select your vacuum gripper and generator.