End-of-Line Packaging (EOLP)

End-of-line packaging (EOLP) defines the final step in the packaging process, in which products are prepared for shipping. This process includes secondary packaging, tertiary packaging, palletizing, labeling, stretch wrapping and sealing of the shipping units.

The aim of the EOLP is to optimally prepare products for transportation, storage and delivery to the end consumer. This also takes into account the protection of the contents as well as the protection of people in the vicinity.

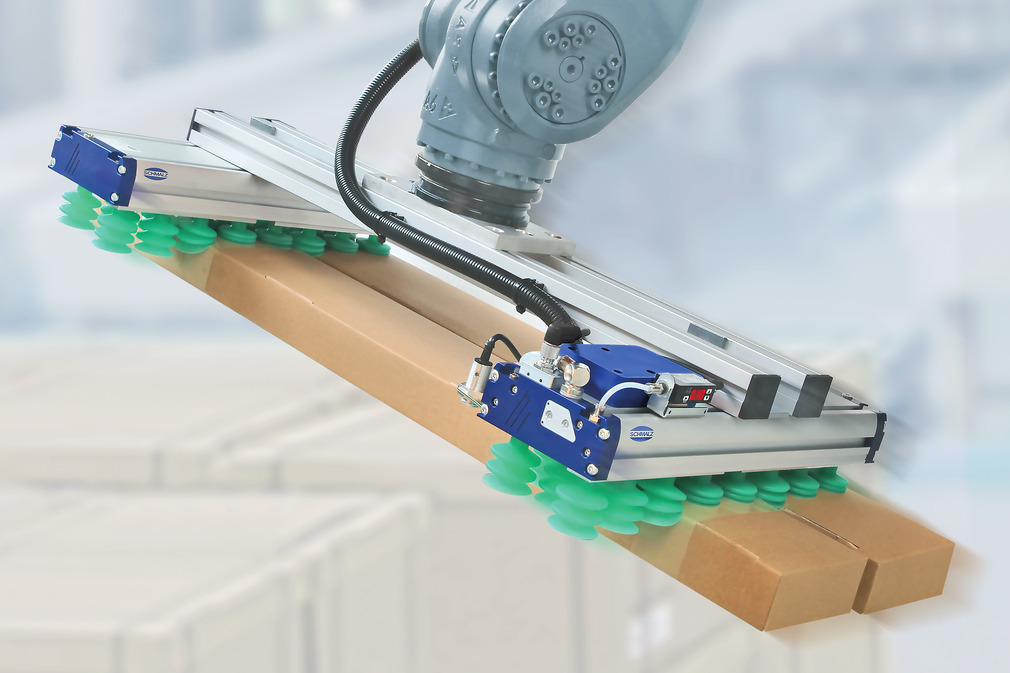

End-of-line automation enables seamless integration into the entire supply chain process through the use of end-of-line packaging machines such as stretch wrappers, case packers and wrappers. This ensures that the end-of-line packaging process is efficient, fast and safe.

Operation mode of EOLP

In the end-of-line packaging process, products are packed in secondary packaging such as cardboard boxes. Stretch film is used to protect the contents and ensure stable packaging.

Once the products have been sealed, they are often palletized onto pallets, which are secured with strapping or other fastening methods. When loading and unloading the pallets, care is taken to ensure that the products are handled in a safe and efficient manner.

Sensors monitor the entire process to ensure that all shipping units are correctly packaged.

It is particularly important to avoid overhang and underhang during palletizing. Overhang (when products protrude over the edge of the pallet) and underhang (when products are too low on the pallet) can jeopardize transport safety and lead to product damage.

The maximum bundle size and the maximum output of the machines are adapted to the requirements of the respective company and the industry solutions.

Where is end-of-line packaging used?

End-of-line packaging is used in a wide range of industries. Typical areas of application include packaging, the food industry, logistics and mass distribution.

In logistics, the end-of-line packaging process ensures the bearing of products and smooth delivery to the end consumer. Packaging solutions are individually adapted to the size and weight of the products to ensure maximum stability.

The protection of the products and the lowest possible product loss rate are also key objectives of the process. Attention is also paid to careful and efficient handling in order to prevent product damage and ensure a high level of transport safety.

The added value of end-of-line packaging technology

The advantages of end-of-line packaging lie primarily in the efficiency and flexibility of the entire packaging process. The use of packaging machines optimizes the process so that products can be prepared for shipping faster and safer.

Seamless integration into networked production systems ensures that the pre-packaging stage is carried out quickly and efficiently, enabling fast delivery.

The process offers great advantages, particularly in working environments that require a high level of user-friendliness and quick adaptations to changing requirements.

Custom-made solutions in material handling enable optimal use of the available workspace. At the same time, transport safety is increased and the integrity of the products is ensured throughout the entire process. This ensures that the products make it through the supply chain undamaged to the end consumer.