Industry 4.0 is made possible only by transparent process and condition data.∼ Dr. Maik Fiedler, Head of Business Unit, Vacuum Automation

Vacuum Technology for the Digital Factory

Vacuum Technology for the Digital Factory

Connected to Control. Schmalz Connect.

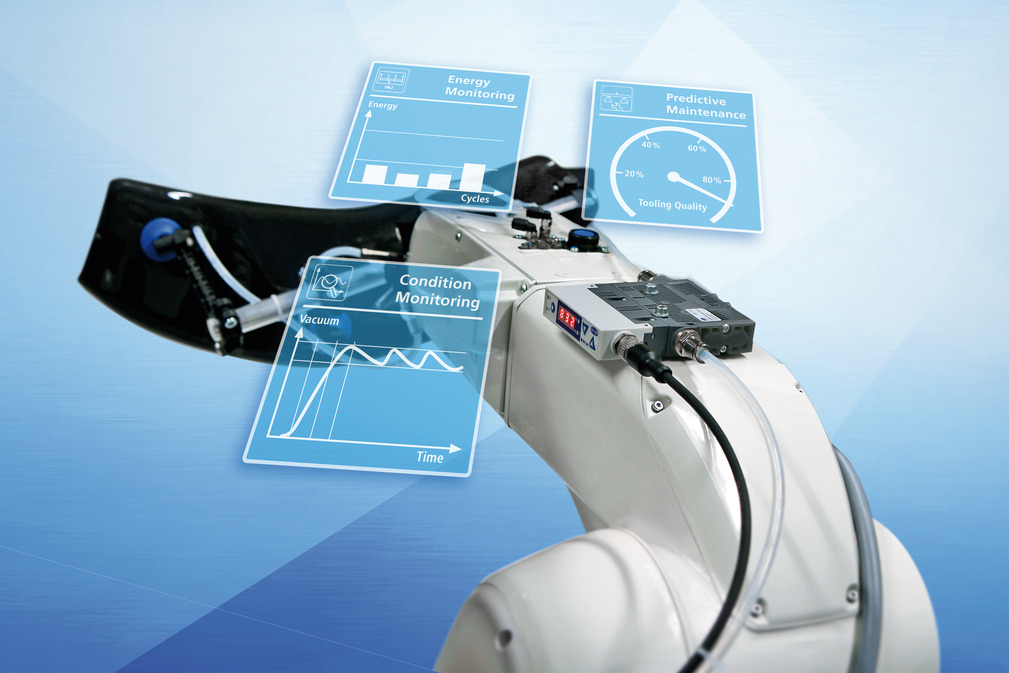

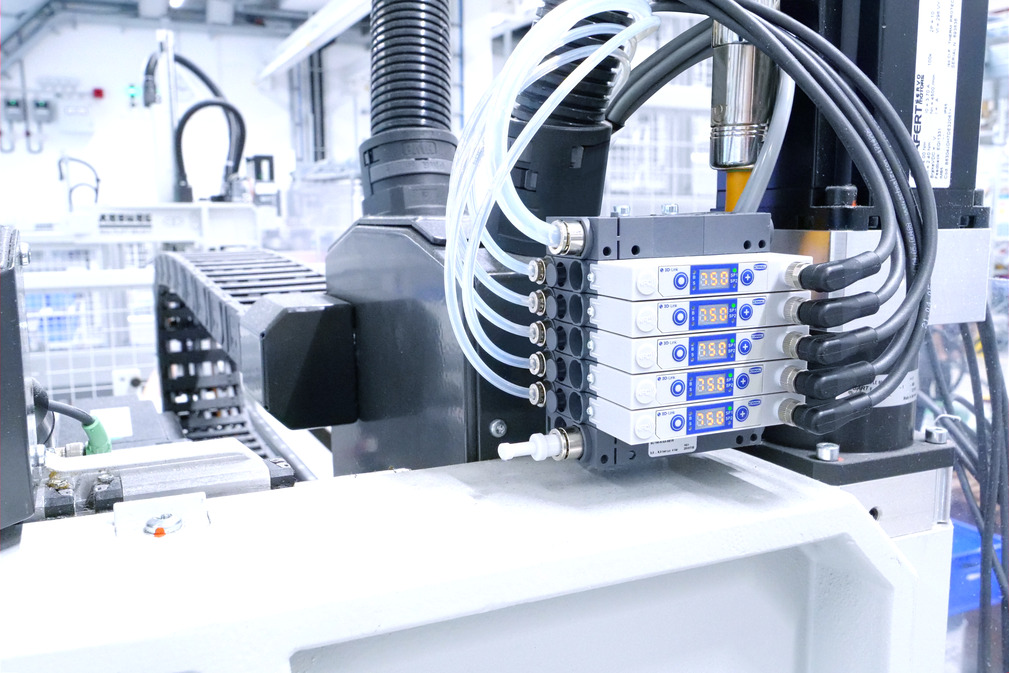

Industry 4.0 thrives on intelligent devices that communicate with each other in the digital factory. In the Schmalz Connect product range, Schmalz bundles a whole range of such smart field devices.

The state-of-the-art vacuum components are quickly integrated into the application environment via interfaces such as IO-Link, Ethernet or NFC. They continually gather and interpret energy and condition data from the process and make it available at the control panel, on the operator's smartphone and in the cloud. Thus a seamless monitoring of the entire process becomes possible, enabling predictive maintenance to prevent downtime and optimize energy consumption.

Benefits of Schmalz Connect

Quick Start of Operations

Ready for immediate use.

Integration via NFC, IO-Link and Ethernet makes the start of operations up to 75 percent faster.

Efficient Operation

Optimum performance.

Monitor and optimize machine data and statuses from anywhere and in real time.

Predictive Maintenance

Increased machine uptime.

Detect subtle changes and reduce the likelihood of imminent malfunctions – before they lead to system downtime.

FAQ - Industry 4.0

Communication interfaces

Added Value Thanks to Digital Processes

Use Cases